Humanoid Robots Are Entering Their Self-Building Era

For decades, the idea of robots building other robots lived firmly in science fiction. Not anymore.

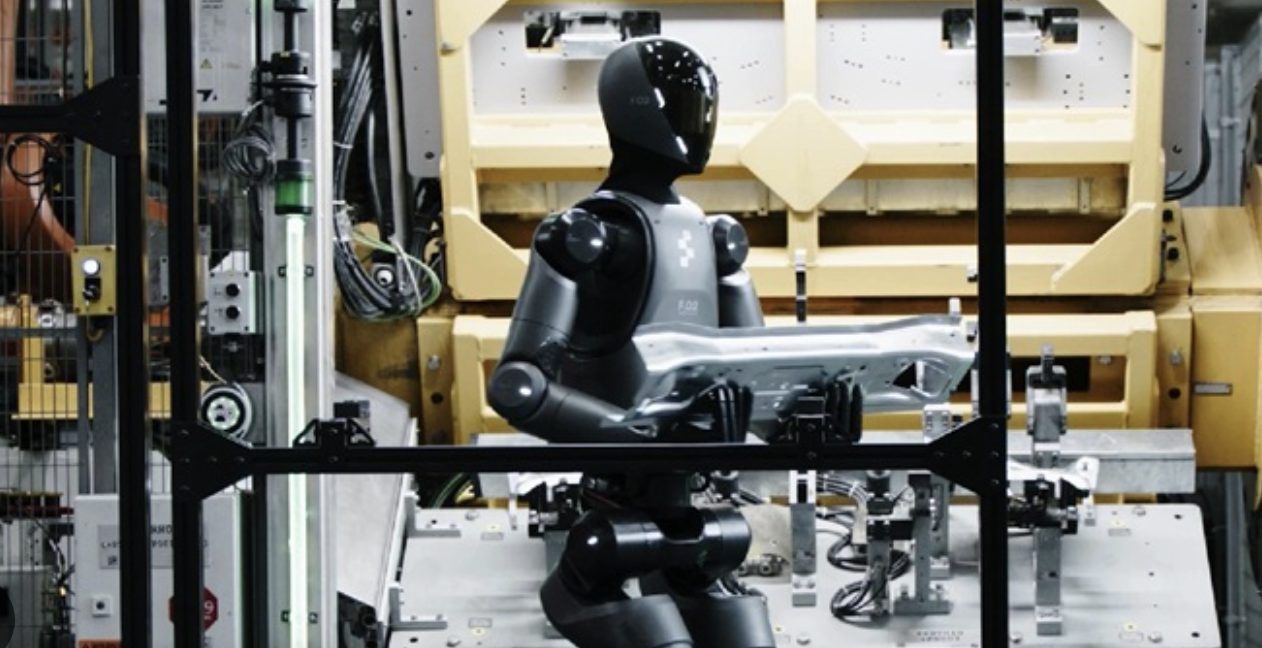

In 2026, something important is happening inside factories around the world. Humanoid robots are beginning to assist in the production of other humanoid robots. Not full self-assembly, not robot babies rolling off the line, but something far more practical and far more powerful.

They are starting to help scale themselves.

What is actually happening right now

Let’s clear up one thing first. No humanoid robot is independently designing, assembling, and shipping another humanoid from scratch. That is not the milestone.

The real shift is simpler and more disruptive.

Humanoid robots are being trained to perform the repetitive, labor-heavy tasks inside humanoid manufacturing lines. These are the jobs that slow factories down and limit how fast production can ramp.

Think tasks like:

Moving parts and subassemblies between workstations

Handling bins, totes, and components

Feeding assembly lines with the right parts at the right time

Performing repeatable subassembly steps

Assisting with inspection and basic rework

This is the “glue work” of manufacturing. It is boring, physically demanding, and incredibly important.

And it is exactly where humanoids fit best.

Real Examples Already Happening

This is not theoretical. Several major players are already putting this idea into motion.

Figure has openly stated that its high-volume manufacturing facility, BotQ, is designed so Figure humanoids can eventually help build other Figure humanoids. The factory is being built with that future in mind from day one.

Apptronik is working with large-scale manufacturer Jabil to bring its Apollo humanoid into real production environments, including assisting in the manufacturing of additional Apollo units.

BMW has already tested humanoid robots on real factory floors, proving they can safely and reliably perform structured tasks in live production settings.

Tesla is training Optimus inside its own factories, using real-world manufacturing tasks to improve dexterity, reliability, and autonomy.

None of these companies are chasing spectacle. They are chasing throughput.

Why humanoids make sense in humanoid factories

Traditional automation works best when the environment is fixed. Humanoid robot manufacturing is the opposite.

Designs change quickly. Parts evolve. Processes are still being refined. Retooling a factory every few months is expensive and slow.

Humanoid robots have one huge advantage here. They are shaped like humans.

That means they can:

Use human tools

Fit into human workstations

Navigate human-designed factories

Adapt to changing layouts without major retooling

Instead of rebuilding the factory around machines, the machines adapt to the factory.

That flexibility is what makes this moment different.

Why this Accelerates Production Faster than People Expect

Factories do not stall because of one complex task. They stall because of thousands of small ones.

When humanoids take over even a handful of repetitive tasks per shift, something important happens. Skilled human workers get freed up to focus on calibration, quality control, troubleshooting, and final assembly.

That accelerates learning curves. It shortens production bottlenecks. It makes scaling less painful.

Most importantly, every robot deployed inside a factory helps make it easier to deploy the next one.

What this Means for Availability

This does not mean humanoid robots are about to flood homes overnight.

The near-term impact shows up first in:

Factories

Warehouses

Logistics centers

Industrial campuses

These are controlled environments where tasks repeat and safety is easier to manage. That is where humanoids will scale first.

Expect production to grow in stages:

First in the thousands

Then tens of thousands

Then much larger fleets as reliability, service, and supply chains mature

As production ramps, costs come down. As costs come down, new markets open.

That is the path from factory floor to everyday life.

The Feedback Loop

This is the real breakthrough.

Humanoid robots are entering a feedback loop where deployment enables production, and production enables deployment.

Each robot on the line generates data. That data improves the next version. The improved version works longer shifts. Longer shifts improve factory output. Higher output makes robots cheaper and more available.

This is not self-replication in the sci-fi sense.

It is something more grounded, and arguably more powerful.

It is self-scaling.

And once that loop stabilizes, the pace of humanoid adoption will no longer feel gradual. It will feel inevitable.