Humanoids are Walking Out of the Labs and onto Jobsites

Humanoid at Work

For years, humanoid robots lived safely behind glass walls, demo stages, and viral videos. In 2026, that boundary is breaking. Humanoid robots are no longer experiments. They are showing up in factories, warehouses, and production environments built for human bodies, not machines.

According to recent analysis from Barclays, advances in artificial intelligence, perception, and mechanical engineering have pushed humanoid robots out of tightly controlled labs and into real workplaces. The shift is subtle but important. These systems are now being tested where people actually work, using human tools, navigating human layouts, and performing tasks people increasingly do not want.

Why Humanoid Robots Now

The timing is not accidental. Labor shortages are growing across manufacturing, logistics, agriculture, and healthcare. Aging populations, urban migration, and changing expectations around physical labor have created persistent gaps. Many of these jobs are repetitive, physically demanding, or hazardous. Traditional automation struggles here because most workplaces were designed around human movement.

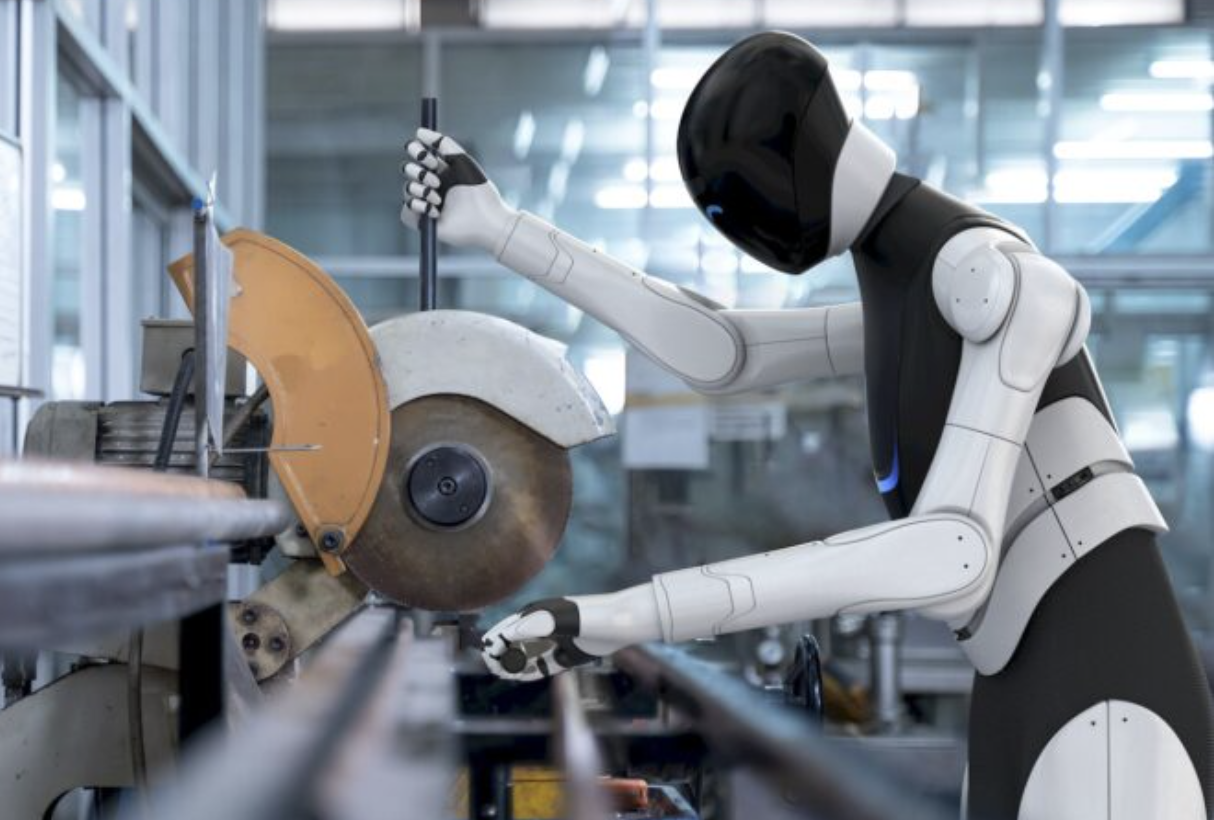

Humanoid robots change that equation. Instead of redesigning the environment, the robot adapts to it.

With arms, legs, sensors, and human-like reach, these machines can move through narrow aisles, climb stairs, operate standard equipment, and switch between tasks without massive infrastructure changes. This makes them uniquely suited for environments that defeat fixed automation systems.

The Technology Finally Caught Up

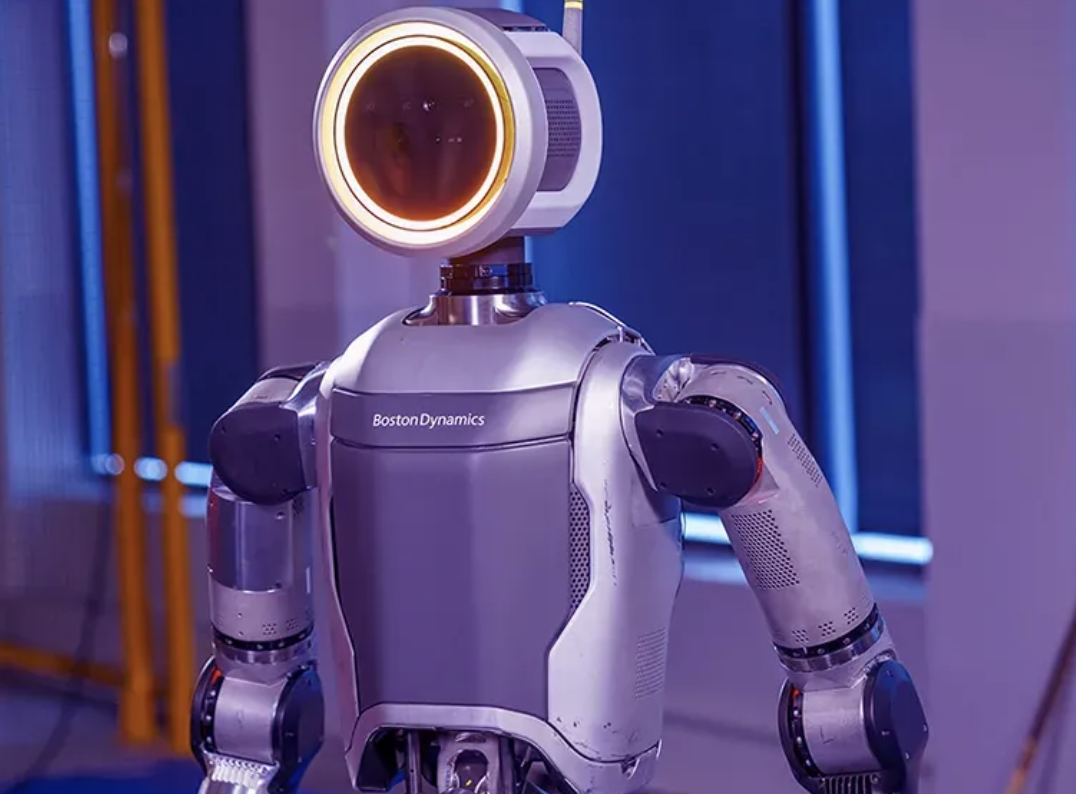

Atlas Humanoid on the Jobsite

Earlier generations of humanoid robots failed for predictable reasons. Poor object recognition, unreliable balance, and limited spatial awareness made real deployment impractical. That is no longer the case.

Modern perception systems allow robots to interpret cluttered, unstructured environments. Motion control has improved to the point where walking, lifting, and manipulation look natural rather than mechanical. Large AI models help robots respond to uncertainty instead of freezing when conditions change.

Public demonstrations at CES 2026 made this clear. Robots like Atlas no longer move like prototypes. They move like workers.

Cost reductions are accelerating adoption as well. A decade ago, humanoid robots cost millions of dollars. Today, production units are approaching the $100,000 range, driven by advances in computing hardware, batteries, and actuators that translate digital commands into physical motion.

Humanoids in Construction.

A Global Supply Chain is Forming

China currently leads large-scale humanoid robot manufacturing, benefiting from scale, speed, and aggressive iteration cycles. Europe plays a different role, supplying many of the high-precision mechanical components that enable reliability and repeatability. This split mirrors the electric vehicle industry, where manufacturing and precision engineering often live in different regions but depend on each other.

The result is a rapidly maturing ecosystem that looks less like a research project and more like an industrial sector.

Humanoids perform dangerous jobs instaed of humans.

Not a Job Apocalypse, but a Shift

Despite the headlines, this is not the end of human work. Energy efficiency still favors humans. Deployment costs remain significant. Supply chains for critical minerals introduce risk. Long-term reliability data is limited.

Most humanoid robots are being aimed squarely at tasks people already avoid. Heavy lifting. Repetitive transport. Dangerous inspection. Overnight warehouse shifts. These are narrow, task-specific roles, not general replacements for human workers.

The bigger change is psychological. Once robots operate alongside people in real environments, the idea of robot coworkers stops feeling theoretical.

What Happens Next

Humanoid robots are not about to flood every industry overnight. But the transition has started. The lab door is open, and machines are stepping into the real world, one task at a time.

The question is no longer if humanoid robots will work alongside humans. It is how quickly we adapt to sharing the workplace with machines that look and move like us.